How Fluid Systems Impact the Cost of Semiconductor Fabs

Why High-Performing Fluid Systems Matter in New Semiconductor Fab Construction

Masroor Malik, Lead Solutions Specialist, Semiconductor

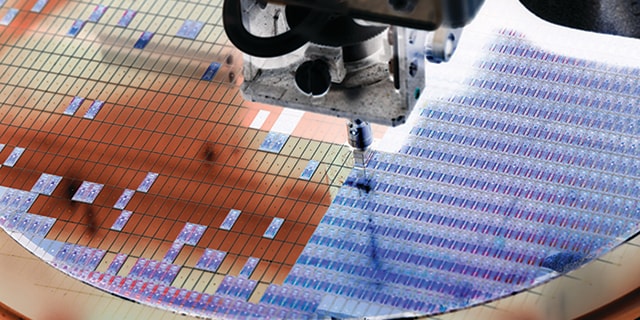

When building a new semiconductor fabrication facility (or “fab”), there are many considerations, including speed to market, material and installation standardization, and overall cost of the semiconductor fab. Many estimates put the cost of a new fab building above $5 billion in most cases. With leading-edge semiconductor fabs (3nm and below) often costing $20 billion or more, the pressure to optimize every system is greater than ever.

Cleanrooms and the expensive microchip fabrication equipment make up the bulk of these expenses, but total cost of ownership can be highly influenced by other systems and equipment throughout the facility.

Fluid management systems, which function essentially as the semiconductor fab’s circulatory system by transporting liquids and gases where needed throughout the facility, are one such example. When approaching new semiconductor fab construction, there is significant opportunity to contribute to the fab’s short- and long-term profitability by specifying high-quality fluid system components and assemblies, and by working closely with fluid system suppliers during the front-end engineering and design (FEED) stage of development.

How to Approach Fluid Systems in Semiconductor Fabs

Here are five ways taking a careful approach to designing and installing fluid systems can contribute to a more profitable semiconductor fab:

#1. Faster, Leak-Tight Installation

Construction of new fab buildings is typically indicative of new production technology and/or capacity expansion, making speed to market a primary objective to stay ahead of the competition. Semiconductor manufacturing and production is expected to begin as soon as possible— often before secondary facilities are completed.

Put simply, there is no time to waste. But designing and constructing complex fluid systems and routing them throughout the fab can be a time-consuming process, involving a significant amount of labor and expertise to properly , install critical components, and ensure total system integrity. This process can be especially difficult if contractors and installers do not have the proper knowledge or training highly reliable, leak-tight systems.

As labor shortages in construction persist globally, custom engineered and prefabricated fluid system assemblies can help eliminate installation issues during construction and remove a significant amount of labor involved in assembling complex subsystems. Look for a supplier that will work to understand your needs and that can provide a complete, easy-to-install assembly made with high-quality components. The time saved can help your fab become fully operational that much faster, enabling full-scale semiconductor production to begin.

#2. More Efficient Planning and Design

Semiconductor fab fluid systems are comprised of a variety of components, including tube fittings, valves, regulators, hoses, and tubing. Proper system planning, efficient design, effective tube routing, and other installation best practices can help contribute to a system that is up and running faster and will be able to perform reliably for the facility’s lifetime.

With growing complexity in multi-wafer processing tools and gas delivery skids, a subsystem that requires a complex series of tubing directional changes can pose a challenge for in-house designers or installers. Working with a supplier that provides a complete subassembly can once again be valuable, as tube bends will have been performed offsite. The complete subsystem will be ready to install and leak-tight upon delivery.

Elsewhere, an efficiently designed fluid system may incorporate numerous tube bends where additional fittings may have been otherwise used. Reducing unnecessary connection points can help save the semiconductor fab builder money on extra parts, and also eliminate potential leak points. Manufacturers can drive down short-term costs during construction, as well as the total cost of ownership over the life of the facility, by specifying higher-quality fluid system components and relying on fluid system design and service experts for support where needed.

#3. Reduced Total Lifecycle Costs

Once the semiconductor fab is in production, operational efficiency and maximized throughput are priorities. Any downtime resulting from a fluid system failure can mean multi-million-dollar production losses per hour, especially in fabs serving AI, automotive, and HPC segments. Sourcing high-quality components and assemblies at the start of the process can help eliminate maintenance, repair, and operations (MRO) requirements over the life of the facility.

For example, thermal stability is increasingly critical, especially for new materials requiring tightly controlled temperature and gas delivery systems. However, if a coolant transport hose is not outfitted with the proper insulation, temperatures in the tool chamber may fluctuate, presenting a challenge to maximum production output. Selecting the right type (and amount) of insulation in hoses from the outset can help reduce the likelihood of any issues, including condensation, which is common in a semiconductor fab environment.

Choosing high-quality components and well-designed systems at the outset of construction will allow for easier and less time-consuming MRO activities. Additionally, fewer necessary component and application replacements will be required over time. The savings and reduced downtime achieved can help the facility remain more productive—and more profitable—for the long-term.

#4. Standardized, Global Quality

Semiconductor fab owners must often consider how to best replicate standards and processes across multiple global locations to ensure maximum production viability and maintain quality requirements.

Standardized fluid system components and applications throughout all facilities can be beneficial. Consistent systems will contribute to easier maintenance, better continuity of installation techniques, and overall safety of production operations. Suppliers that provide globally consistent products specs, just-in-time logistics, and local field support are essential to meeting regional compliance requirements while staying on schedule. Working with these organizations across facilities can lead to efficiencies and design choices that yield sizable profitability improvements worldwide.

#5. Increased Productivity and Throughput Yield

Once a semiconductor fab is commissioned and operational, ensuring you have systems that maintain stable flow, resist particle shedding, and eliminate the need for frequent shutdowns can directly enhance chip yield and fab uptime. Production reliability can help a producer gain or maintain their edge in this highly competitive industry.

In today’s semiconductor fabs, yield drops of even 0.5% can mean tens of millions of dollars in lost value annually. Fluid system reliability is now part of the ROI conversation from day 1. But as we have seen, sourcing higher-quality parts, components and subassemblies for critical fluid systems throughout the fab can contribute to numerous benefits and overall lower cost of ownership for the lifetime of the facility.

Small Changes Can Reduce the Cost of Semiconductor Fabs

With new semiconductor fabs coming online across the globe and geopolitical pressure to accelerate domestic capacity in each region, every design choice matters. High-quality fluid systems are no longer just a reliability asset, but a strategic enabler of competitiveness and return on capital.

Interested in learning more about maximizing the performance and cost effectiveness of your fluid systems? Swagelok has helped semiconductor producers design and build fluid systems around the world. Get in touch with our teams to find out how our design and assembly services and other tailored support capabilities can help with the construction of your next fab.

Related Semiconductor Articles

Optimize These Applications for More Profitable Semiconductor Fabs

As semiconductor fab construction booms around the world, manufacturers should consider how optimizing critical industrial fluid system applications can contribute to more efficient and profitable operations.

Small Changes to Hose Installation Practices Can Mean Big Semiconductor Manufacturing Savings

How to reduce costs by avoiding issues like hose condensation and energy loss in semiconductor manufacturing by following proper hose installation practices.

Improve Semiconductor Wafer Manufacturing Yield With Proper Thermal Control

Semiconductor wafer manufacturing requires precise process and temperature control. Learn how optimizing thermal controls throughout the semiconductor tool ecosystem can lead to less downtime, higher yields, and increased production efficiency.