Hydrogen Tubing System Training

The Swagelok® Tubing System Training Program, Hydrogen Applications

Building fluid systems designed to overcome these challenges requires the right components, the right materials, the right expertise, and the right training. That is why we developed the Swagelok® Tubing System Training Program for hydrogen applications. This program provides hands-on training for those responsible for designing, installing, maintaining, and/or inspecting H2 tubing systems.

About the Course

Topics

This training program is designed to provide knowledge and understanding of:

- What is Hydrogen?

- Hydrogen Compatible Materials

- Risk Mitigation and Best Practices

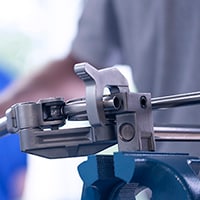

- Tube Fitting Installation

- Tube Bending

- Tube Fitting Installation Inspection

- Higher Pressure Module

- FK Medium-Pressure Tube Fittings

- Cone and Thread Fittings

- Leak Testing

- Knowledge Test

Target Audience

Target Audience

TSTP hands-on training is ideal for installers, technicians, engineers, designers, QC/QA inspectors, and others responsible for designing, installing, maintaining, and/or inspecting tubing systems in hydrogen and small molecule gas delivery systems.

Course Format

Designing, engineering, installing, and maintaining a high-performance hydrogen tubing system for maximum safety and integrity means starting with the basics. That is why this training program provides in-depth, comprehensive focus areas beginning with a foundational understanding of H2 and progressing through critical aspects such as materials science, installation, tube bending, and fitting technologies.

Successful attendees will receive a Swagelok® Certificate of Completion which is valid for three years. For added customer assurance, training certificates are tracked using a centralized Swagelok Customer Training Records System. This enables those who have completed the course and their employers quick and easy verification of training records.

Course Duration

One and a half (1.5) days in-person.

Instructor

This course is facilitated by a Swagelok-certified subject matter expert.

How to Register

Sign up below for tubing system training. Your local authorized Swagelok sales and service center will follow up with full details.