Corrosion Resistance Hub Page

Materials Matter: Selecting the Right Material for Corrosion Resistance

An offshore platform can have nearly 50,000 feet of tubing, more than 20,000 fluid system components, no fewer than 10,000 fittings, and as many as 8,000 mechanical connections. That’s why when selecting materials, it is important to choose corrosion resistant metals.

There are numerous aspects to consider when specifying materials to help manage corrosion. Many considerations go beyond the material itself. Although initial quality of material and manufacturing is important to fluid system component longevity, finding a provider with materials science expertise and the ability to support you in your materials selection decision-making can also make a difference when building fluid systems that resist corrosion.

Quality Control Measures

Quality Control Measures

Just about every metal corrodes under certain conditions. Corrosion happens when a metal atom is oxidized by a fluid, leading to a loss of material in the metal surface. This reduces the thickness of a component, for example, tubing, and makes it more prone to mechanical failure. Many types of corrosion can occur, and each type poses a threat that must be evaluated when selecting the optimal corrosion-resistant materials for your application.

While the chemical composition of the material affects corrosion resistance, one of the most important factors in reducing failure due to material defects is the overall quality of the materials used. From bar stock qualification to final inspection of components, quality should be part of every transaction.

Want to learn more about selecting the right materials to resist corrosion? Browse our Materials Selection Guide.

Material Process Controls and Inspection

The best way to prevent a problem is to detect it before it happens. One way to do this is to ensure that the supplier has stringent quality control measures in place for corrosion prevention, beginning with process controls and inspection of bar stock. Inspection can take many forms, from visually ensuring the material is free from surface flaws, to using non-destructive testing techniques, to performing specialized tests that detect susceptibility to corrosion.

Tour of our corporate raw materials facility to learn about the importance of validating material quality

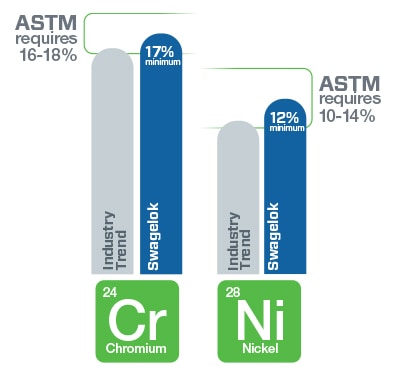

Another way a supplier can help you verify the material’s suitability is to check for levels of specific elements in the material’s composition. For corrosion resistance, strength, weldability, and ductility; the starting point is an optimized composition of an alloy. As an example, greater quantities of nickel (Ni) and chromium (Cr) in Type 316 stainless steel than minimally required by American Society of Testing and Materials (now ASTM International) standard specifications result in materials with better corrosion resistance. A supplier should always provide the chemical composition of a material and indicate compliance with standards published by the International Standards Organization (ISO) and ASTM International.

During Manufacturing

Ideally, a supplier should inspect components at every step in the manufacturing process. A first step is verifying that proper manufacturing work instructions have been followed. Once the components are manufactured, further testing should confirm that the parts have been built correctly, with no visual defects or other imperfections that could hamper performance. Additional testing should ensure that components operate as intended and are leak-tight.

Materials Science Expertise

Materials Science Expertise

Once you know that the material and the resulting components meet or exceed standards for performance, the next step is to make the right selections to address concerns integral to your operating environment. That’s the difference a supplier with a foundation in materials science can make.

On the technical side, considering factors such as mechanical properties and material compatibility can help you understand how to make the right choices.

Mechanical Properties

Mechanical Properties

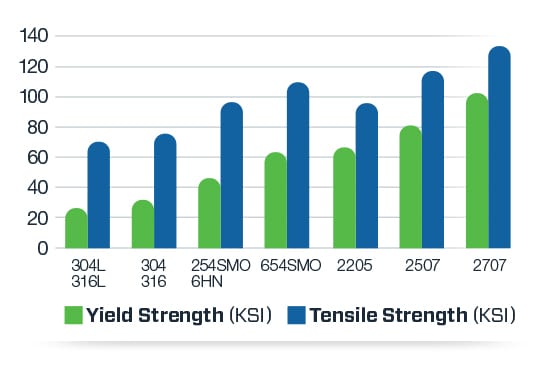

A material’s mechanical properties include its yield strength, tensile strength, and ductility. Higher-strength materials can be used to fabricate components that must work reliably at high pressures.

Material Compatibility

Material Compatibility

Corrosion can be an expensive problem. NACE International estimates the recent total annual cost of corrosion at $1.4 billion USD for the entire oil and gas production industry. But when you can visually identify corrosion and know where to look for it, the risk can be minimized. Better yet, when engineers can anticipate corrosion and make the best material choices; system integrity, longevity of assets, performance, and safety improve.

Take these steps to reduce the impact of corrosion on your applications:

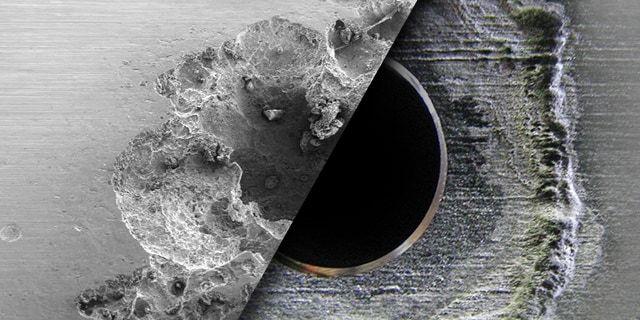

- Identify types of corrosion– what it looks like, where it occurs, and why it happens

- Select materials resistant to corrosion

- Minimize locations where corrosion can occur and reduce contact with non-compatible metals

- Specify everything from the supports and clamps to the tubing itself to reduce the potential for corrosion

Ongoing Support

Installing fluid system components made from premium materials is only the beginning, however. To ensure your application’s longevity, it’s vital to have ongoing support after your purchase. Be sure to select a supplier who knows your challenges and can recommend and support solutions that protect your material investments.

For example, we offer in-depth materials science training taught by experts with doctorates in materials science and metallurgical engineering. These courses are designed to help fluid system professionals the knowledge needed to select components comprised of the right materials to provide long-lasting performance in challenging end-use environments. Reach out to schedule training at the link below, or to seek additional guidance on resisting corrosion.

Related Articles

Pitting Corrosion vs. Crevice Corrosion: What’s the Difference?

Stainless steel corrosion is a major challenge for oil and gas operators everywhere, but it can be prevented. Learn how to identify the differences between pitting corrosion and crevice corrosion.

Enhance Safety and Save with Optimized Materials

Discover how offshore platform owners can optimize their material selection for tube and tube fittings to control costs and enhance safety in a variety of applications.

Video: The Importance of Materials Selection

Learn about the importance of choosing the correct materials for your fluid system.