The Swagelok Tube Fitting Advantage

The Swagelok Tube Fitting Advantage

Proven design, manufacturing excellence, and superior raw materials combine to ensure that every Swagelok fitting meets our customers’ highest expectations. When properly installed, Swagelok’s two-ferrule, compression-grip tube fittings produce a repeatable, leak-tight seal, even after being reassembled multiple times.

See how Swagelok tube fittings help you reduce leaks and improve your operations:

The Lowdown on Leakage

Choosing the most reliable fittings and installing them correctly can save you money and make the workplace safer. Consider the many costs and consequences of leakage:

Lost Production

Especially important in offshore oil where laws already limit production to a specific number of days per month

Off-Specification Product

Can be produced inadvertently due to improperly calibrated or operating instruments; material must be reworked, sold at reduced price, or disposed of

Degraded Work Environment

Oil drippage can cause accidents; emissions can be expensive, dangerous — even illegal

1. Better by Design

We outperform other fittings in three key areas — tube grip, gas seal, and vibration resistance.

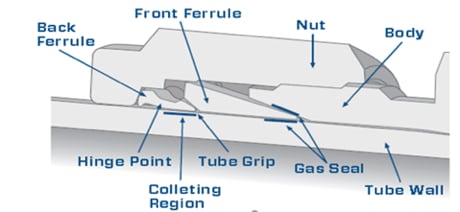

Repeatable, leak-tight connections

Swagelok tube fittings have a grip-type design that uses a unique “hinging and colleting” action to achieve optimal performance in three key areas.

- Tube grip: hinging and colleting action provides more direct tube contact/gripping support.

- Gas seal: burnishing and polishing action of the front ferrule creates concentrated zones of contact on the tube and on the body bevel for a stronger seal.

- Vibration resistance: the colleting region better isolates stress risers at the tube grip to resist bending, deflection, and vibration.

SAT12® Carburization Process

Swagelok’s unique low-temperature carburization process provides tool-steel-like hardness and strength in the rear ferrule without sacrificing corrosion resistance or material ductility.

Easy to Install

Quick assembly and reassembly using only standard wrenches make our fittings easy to install. Our expert training equips your workforce with essential skills for installing fittings across all your applications.

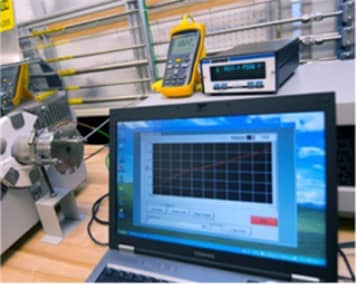

Rigorous Testing

Swagelok fittings are subjected to extreme burn, rotary flex, impulse, corrosion, and shock impact testing. Some tests take as many as 10 million cycles to complete.

Thousands of samples of production tube fittings are tested in our state-of-the-art labs to ensure only highly reliable components.

We offer the most comprehensive tube fitting Product Test Reports (PTRs) in the industry.

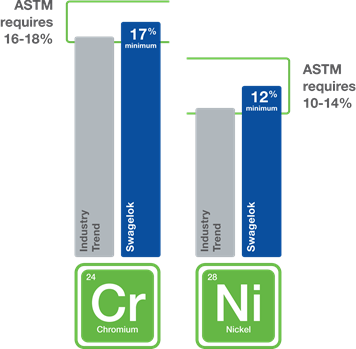

2. A Material Difference

In all stainless steels, chromium and nickel are critical for corrosion resistance and ductility. Because our 316 SS tube fittings contain more chromium and nickel than industry standards require, you can make the most of resources while achieving optimal performance by combining our 316 SS fittings with compatible alloy tubing in Engineered Combinations.

3. Low Cost of Ownership

The price of a fitting is only part of its actual cost. Swagelok two-ferrule, compression-grip fittings cost less to own over the life of the fitting. Better design and reliability mean less investment in replacement and more investment in your operation.

- Leak-tight design = less risk of costly accidents and media loss

- Optimal reliability = lower maintenance costs and minimal downtime

4. Services Tailored to You

Swagelok can support your success wherever it takes you. Our 7,800 associates worldwide work together to provide factory support, field engineering, technical services, coordinated deliveries, inventory replenishment, and a range of special expertise.

See how our evaluation and advisory services can help relieve your pressures

Training

Discover a variety of training courses designed to enhance your critical skills for developing, building, and maintaining high-performing fluid and sampling systems, with topics covering everything from orbital welding to advanced tube bending, to sampling subsystem design.

Onsite Services

Boost system safety, performance, and efficiency with prioritized, actionable recommendations from Swagelok experts based on fluid and sampling system site surveys, hose advisors' observations, or steam system audits.

Design and Assembly Services

Come to Swagelok for design consultation and construction of high-quality standard and configurable fluid and sampling systems assemblies, from grab sampling and mechanical seal support systems to analytical subsystems and gas distribution panels.

Business Support

Take advantage of purchasing, procurement, and inventory management support, and make the most of our product selection consulting services.